Integrating your heat exchangers into IT solutions can optimize technical sales processes, increase efficiency, improve product performance, and strengthen customer service.

We are experts in heat exchanger IT solutions.

Last finished projects

We understand your technical requirements for heat exchangers.

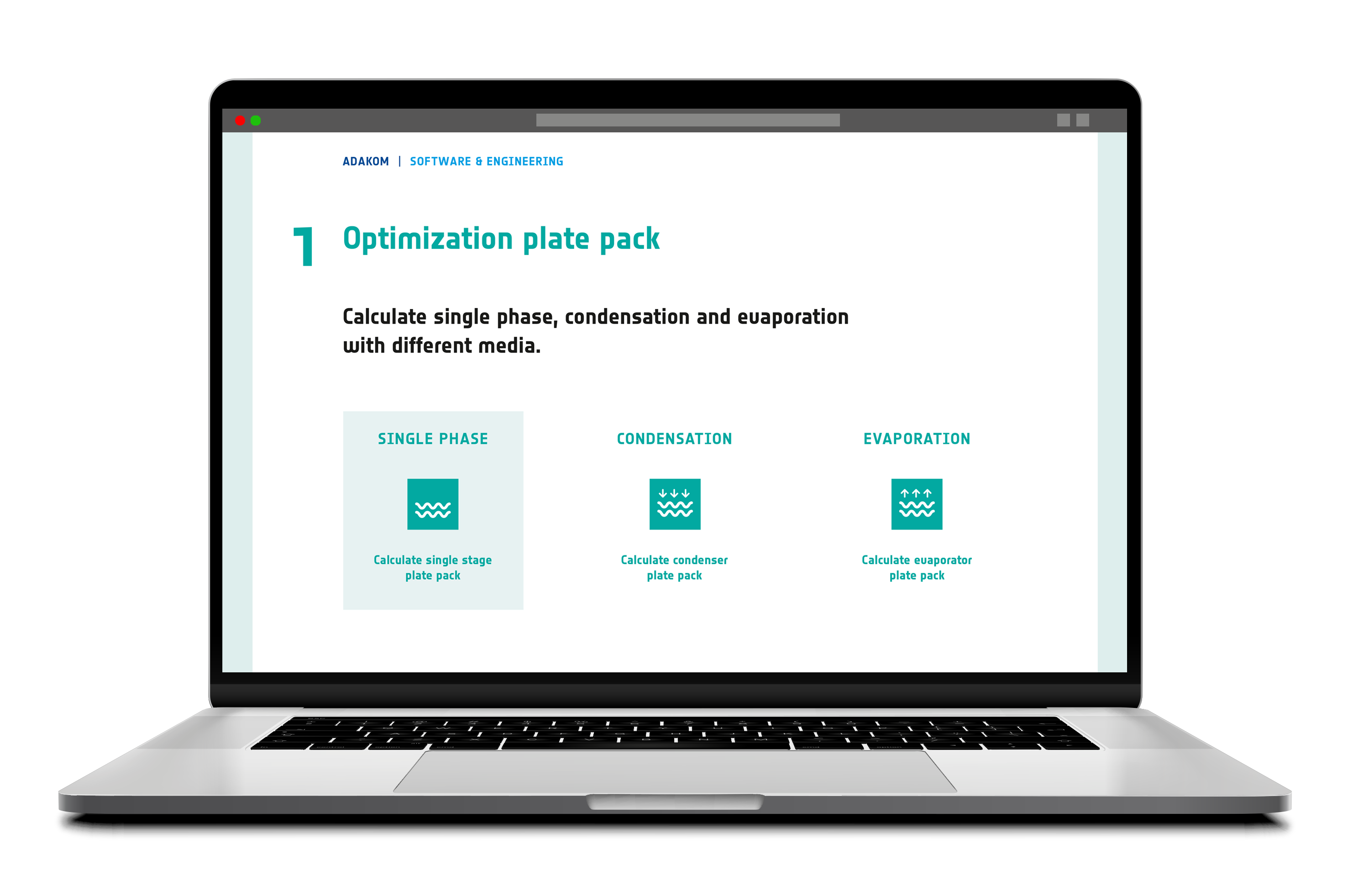

Design software for manufacturers

Tailor-made software solutions and web-based services for the design of your heat exchangers. These solutions are integrated into your software landscape and workflows.

Show demo

Thermohydraulic modeling

Develop models for you to describe the behavior of fluid flows and heat transfer processes within your heat exchangers according to the latest scientific findings. Read more

Rest Interfaces

Provide a RESTful API that enables you, as a heat exchanger manufacturer, to offer your customers seamless integration into their own systems and processes, which can improve efficiency and increase customer satisfaction.

Read more

Our services selects the optimized heat exchanger plate pack with appropriate process and boundary conditions.

Together we analyze the efficiency of your heat exchangers

Measurement & optimization

Ensure the long-term performance and reliability of your heat exchanger during operation. This includes energy savings, extending the service life and minimizing downtimes.

Read more

Monitoring

Scoring for heat exchangers in operation as a function as a service or stand-alone web solution for the efficiency and performance of your devices in operation.

Show demo

Simulation

The target state of the heat exchanger in operation and the simulation of different load cases helps you to make predictions about the operating state and fouling state of your devices.

Show demo

The experts at Adakom continuously extend their portfolio in the area of technical solutions for heat exchangers through the development of thermic models, customized configurators and services.

Milestones

-

1998Founding of the Adakom GmbH by Volker Brandt and a team of engineers

-

2002First tool for integration with a CRM/ERP System

-

2004Development of a two-phase module

-

2005Target value process for heat exchanger optimization in a cell-model

-

2007First accompaniment of measurements of heat exchangers

-

2014Measurement of heat exchangers in a plant operation

-

2017Start of a project for mobile measurement of heat exchangers in collaboration with the TU and PTB

-

2018Expansion of the team to strengthen the projects on the integration of the heat exchangers

-

2019API development for web interpretation

-

2022Flow diagram for plate heat exchanger

-

2023API development for CPQ and document generation

-

2024Anja Stipp-George and Volker Brandt lead the Adakom GmbH into the future

Sizing and configruation of

-

1998Brazed and tube bundle heat exchanger

-

2002Gasket plate heat exchanger

-

2007Plate and shell heat exchanger

-

2010Tube and fin as well as finned tube heat exchanger

-

2012Hybrid cross-flow heat exchanger

-

2014Fully welded heat exchanger with fully customizable flow schemes

-

2015Additional tube and fin as well as finned tube heat exchanger

-

2017Compact tube-fin heat exchanger

-

2019Transformer cooling system

-

2020Double tube safety system

-

2021API for customer version

-

2022API for operating data acquisition and evaluation

We are looking for

We have exciting projects in a growing company with work-life balance culture. We look forward to you. Please send your application to: jobs@adakom.de.